Recycling overview¶

Authors and date

- Submitted on: July 12th 2021

- Emmanuelle Frenoux, Senior lecturer, Paris-Saclay University

- Juliette Chabassier, Research Fellow, INRIA

- Anne-Laure Ligozat, Lecturer at LISN and ENSIIE

This sheet, automatically translated by the Deepl tool, has not been proofread by its author

WEEE - a definition¶

A waste is, legally, an object that the holder discards or intends or is obliged to discard. It can therefore be an object that is still functional.

WEEE corresponds to waste electrical and electronic equipment. It includes all waste equipment that uses an electrical plug, a battery or an accumulator, as well as all their components and the consumables associated with them. They are marked with the symbol of the crossed-out garbage can:

This includes, for example, household appliances, computers, freezers from your supermarket, your dentist's electric chair, or network equipment from your internet service provider. Among the WEEE is therefore digital equipment waste.

The management of WEEE theoretically follows two main steps:

- the collection, i.e. the recovery of equipment that is no longer used by local authorities (waste collection centers for example), distributors (in-store returns), social economy actors or eco-organizations (direct collection in companies and organizations, solidarity collections in some cities...). Not all WEEE produced in a country is collected: in France the collection rate was about 50% in 2019 (source: ADEME register), and globally 17% (source: Global e-waste monitor 1) .

- the treatment of WEEE, trying to promote the reuse or recovery of all or part of the equipment. The possible types of treatment are, in order of priority (in theory): preparation and/or reuse of the whole equipment or sub-assemblies of the equipment; material recycling (about 75% of WEEE treated in tonnage); energy recovery (incineration with heat recovery); disposal (landfill, burial or incineration without energy recovery).

In reality, these two stages do not always take place as indicated above for collection. A small portion of the WEEE collected is also not processed in France.

Collection¶

Principle and collection rate¶

At the global level, a consortium of institutes has worked to establish a methodology for estimating the quantity of WEEE based on the quantities of items placed on the market. Their findings are available and regularly updated in the global E-waste monitor1. The collection rate in each country is then calculated using the volume of WEEE collected against this estimated quantity of WEEE.

As previously mentioned, in France the collection rate was approximately 50% in 2019, and globally 17%. Despite recurring incentives to bring back WEEE with the aim of increasing the French collection rate, a large proportion of WEEE is still not collected but resides in closets, in household waste, in scrap metal, in illegal dumps or in informal channels, for export (often under the guise of donation).

Who is responsible for the collection?¶

The principle of Extended Producer Responsibility implies that producers must set up a collection and treatment system for equipment. These channels are partly financed by an eco-tax on the purchase of new household appliances. The collected equipment (in the store or via a specific channel of the manufacturer or in the waste disposal center) is given to the approved eco-organizations for treatment (re-use, repair, preparation for recycling...).

French producers are also required to declare annually to the ADEME Registry the quantities of electrical and electronic equipment placed on the market, collected and processed. Based on the analysis of these data, ADEME publishes an annual report allowing the monitoring of the electrical and electronic equipment sector in France and the calculation of collection and recycling rates.

How much digital equipment is in WEEE?¶

Since 2018 in France, EEE is classified into 7 categories of equipment (thermal exchanges, screens, lamps, large appliances, small appliances, computers) with an objective of tracing and monitoring. On the other hand, on collection sites, the flows are rather organized according to 6 major categories, the digital not being differentiated from other equipment.

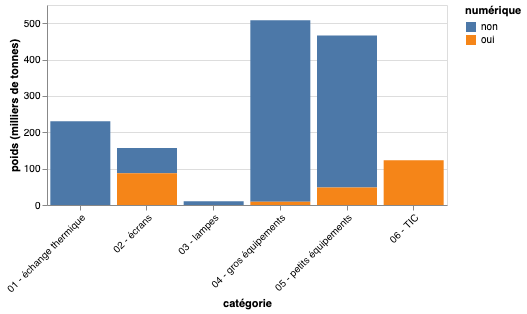

However, we can estimate the proportion of digital equipment in each category. In 2018, about 18% of the WEEE mass can be considered digital (see Figure 1).

Figure 1 - Tonnage of WEEE by category in France in 2018 (in thousands of tons) - Data taken from Implementation of the WEEE Directive

The pollution generated (see next section) depends more on the composition of the equipment and its structural complexity than on the total mass. The pollution generated by digital WEEE therefore certainly represents a higher proportion than its 18% in mass: the components of digital equipment are often miniaturized and intermingled to such an extent that it is complicated to separate the materials in order to recycle them, and this separation and recycling is done at the cost of a significant pollution (emission of toxic gases, use of acids, large quantities of water, heating at very high temperatures, etc.).

Paradox of the incentive to collect¶

Currently, the collection and recycling system faces a paradox that can no longer be ignored: the approval of eco-organizations is based exclusively on the weight of WEEE collected, without taking into account the rate of reuse achieved. This policy can have several negative consequences:

- inciting the said eco-organizations to integrate all the collected material into the weight of WEEE, without setting up reuse, since the latter, although being the most ecological choice, is not taken into account,

- provision of skips to facilitate and "automate" the collection: in skips, the material is crushed, which then makes it unsuitable for reuse.

Treatment¶

The processing chain¶

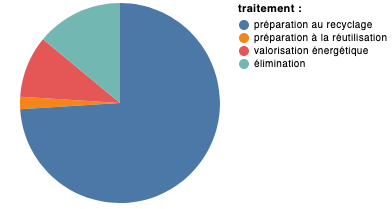

The processing of collected equipment leads to several possible routes: preparation for reuse (about 2% in France in 2019); recycling (about 75%); energy recovery (about 10%); and elimination, i.e., landfill and burial, or incineration without energy recovery (about 14%).

Figure 2 - Types of WEEE treatment in France in 2019 - data extracted from Ademe 2020 register (2019 figures)

In reality, only 75% by weight of the WEEE collected is therefore injected into a real WEEE recycling system (and this figure is quite variable depending on the type of equipment). Given the collection rate in France (50%), this represents only 38% of the mass of WEEE generated (at best).

The preparation for recycling generally takes place in six stages (source: ADEME register):

- dismantling (separation of different components) and depollution (extraction of polluting substances);

- crushing of equipment into small pieces;

- electromagnetic separation of ferrous elements using magnets;

- optical sorting to separate the electronic cards, which are then recycled via another recycling process to recover the strategic metals contained in these fractions;

- separation of non-ferrous metal elements (including copper) using eddy currents;

- separation of plastics by flotation or optical sorting.

These processes lead to an average recovery of 11% of the mass of materials (figure for 2019 for all WEEE). At the exit of these WEEE treatment centers, the fractions of electronic cards, plastics, etc. are sent to specialized factories which in turn will try to recover as much secondary material as possible which will be re-injected into factories producing goods. There are very few factories capable of recycling a wide variety of metals from an electronic card. UMICORE (in Belgium) and BOLIDEN (in Sweden) are the most efficient in Europe; there is no equivalent in France.

Processing limits¶

In general, the treatment for recycling WEEE has a lower environmental impact than the production of the recovered materials, and is therefore interesting from an environmental point of view: this is the case for copper, aluminum, precious metals in general (gold, palladium, silver) but not for tantalum for example.

However, its impact is far from being negligible.

The industrial processes involved use a lot of energy (material/energy duality) in order to heat the materials to be recycled to high temperatures.

Moreover, to de-alloy rare metals and rare earths, it is necessary to use acids and salts and to heat them to very high temperatures (energy).

One of the reasons for these difficulties in extracting metals is that they are intimately mixed in the miniaturized terminals, and trying to extract the constituent elements (in the chemical sense of the term) is like trying to extract the initial ingredients like the tomato and the zucchini from a spoonful of ratatouille (allegory freely inspired by Philippe Bihouix).

In the end, the recycling rate of ICT metals is low or even extremely low (less than 50% for more than half of them, for some less than 1%) and therefore does not allow us to cover 100% of our needs in raw materials, not to mention the loss during melting. In any case, 100% coverage of our needs is not possible in a context where the demand for materials for the manufacture of our equipment continues to grow (see Concept sheet "What are the limits of the circular economy?"Concept sheet "What are the limits of the circular economy?" ).

Moreover, the price of some recycled metals on the market can be higher than primary metals, thus not encouraging the development of recycling channels (reference: Les minerais dans l'économie circulaire : l'économie des métaux. Florian Fizaine. see https://www.youtube.com/watch?v=FLq9bb3Befg)

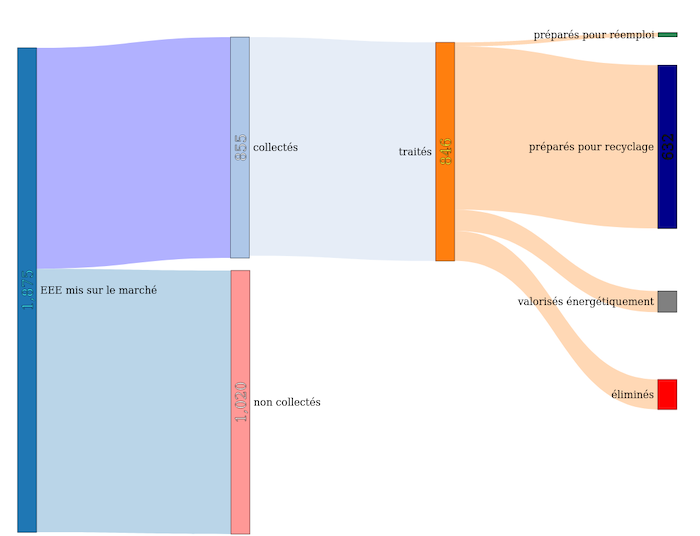

Graphical summary of WEEE management in France¶

Figure 3 - WEEE treatment flows in France in 2019 in thousands of tons - data extracted from the Ademe 2020 register (2019 figures)

Glossary¶

Eco-organization: a private company owned by producers and distributors to manage the end-of-life of the equipment they put on the market, as part of the Extended Producer Responsibility (EPR) program (source: Wikipedia)

WEEE: Waste Electrical and Electronic Equipment

ADEME: French Agency for Ecological Transition

Sources used for this document¶

- Directive européenne 2006/12/CE de 2006 pour la définition d'un déchet

- Décret définissant les DEEE

- The Global E-waste Monitor, url

- ADEME, Erwann FANGEAT. In Extenso Innovation Croissance, Alice DEPROUW, Marion JOVER, Mathilde BORIE, Océane TONSART. 2020. Rapport annuel du registre des déchets d’équipements électriques et électroniques, url.

- Recycling Rates of Metals, A Status Report. UNEP (United Nation Environment Programme), 2011

- Does WEEE recycling make sense from an environmental perspective?: The environmental impacts of the Swiss take-back and recycling systems for waste electrical and electronic equipment (WEEE), R. Hischier, P.Wäger, J.Gauglhofer, Environmental Impact Assessment Review, Volume 25, Issue 5, July 2005, Pages 525-539

- Flore Berlingen. Recyclage Le Grand Enfumage. Ed. Rue de l’échiquier, 2020

- Demand and criticality of some metals involved in the energy transition, O. Vidal et al. Metals for a low-carbon society. Nature Geoscience, vol. 6, n° 11, 2013